Product Description

WH14 heavy load worm drive slewing gear reduction for man lift working platform

1. Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008.

2. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements.

3. With abundant raw materials and high production efficiency, the company can supply products to customers as quickly as possible and shorten the time for customers to wait for products.

4. Our internal quality control includes first inspection, mutual inspection, in-process quality control and sampling inspection to ensure product quality. The company has complete testing equipment and advanced testing method.

5. Strong after-sales service team, timely solve customer problems, to provide customers with a variety of services.

Our Services & Strength

1.Raw material from reliable suppliers;

2.Production process is in strict accordance with ISO9001 Quality Management System .

3.Strict in-process quality control and 100% finished product inspection before delivery;

4.Third party product inspections are acceptable CZPT customer request.

5.Adoption of standardized product design process and APQP, PPAP, FEMA for application analysis.

Production photo

WH14 heavy load slewing drive worm drive turntable on aerial working platform

Coresun Drive makes the salt spary testing and painting thickness testing for ensuring the quality of corrosion protection.C3 or C4 standard as the customer’s requirement.

CONTACT US

It is sincerely looking CZPT to cooperating with you for and providing you the best quality product & service with all of our heart!

| Material: | 42CrMo |

|---|---|

| Holding Torque: | 48kn.M |

| Tilting Moment Torque: | 72kn.M |

| Output Torque: | 6.8kn.M |

| Output Speed: | 2.1rpm |

| Gear Ratio: | 84:1 |

| Customization: |

Available

| Customized Request |

|---|

Hypoid Bevel Vs Straight Spiral Bevel – What’s the Difference?

Spiral gears come in many different varieties, but there is a fundamental difference between a Hypoid bevel gear and a Straight spiral bevel. This article will describe the differences between the two types of gears and discuss their use. Whether the gears are used in industrial applications or at home, it is vital to understand what each type does and why it is important. Ultimately, your final product will depend on these differences.

Hypoid bevel gears

In automotive use, hypoid bevel gears are used in the differential, which allows the wheels to rotate at different speeds while maintaining the vehicle’s handling. This gearbox assembly consists of a ring gear and pinion mounted on a carrier with other bevel gears. These gears are also widely used in heavy equipment, auxiliary units, and the aviation industry. Listed below are some common applications of hypoid bevel gears.

For automotive applications, hypoid gears are commonly used in rear axles, especially on large trucks. Their distinctive shape allows the driveshaft to be located deeper in the vehicle, thus lowering the center of gravity and minimizing interior disruption. This design makes the hypoid gearset one of the most efficient types of gearboxes on the market. In addition to their superior efficiency, hypoid gears are very easy to maintain, as their mesh is based on sliding action.

The face-hobbed hypoid gears have a characteristic epicycloidal lead curve along their lengthwise axis. The most common grinding method for hypoid gears is the Semi-Completing process, which uses a cup-shaped grinding wheel to replace the lead curve with a circular arc. However, this method has a significant drawback – it produces non-uniform stock removal. Furthermore, the grinding wheel cannot finish all the surface of the tooth.

The advantages of a hypoid gear over a spiral bevel gear include a higher contact ratio and a higher transmission torque. These gears are primarily used in automobile drive systems, where the ratio of a single pair of hypoid gears is the highest. The hypoid gear can be heat-treated to increase durability and reduce friction, making it an ideal choice for applications where speed and efficiency are critical.

The same technique used in spiral bevel gears can also be used for hypoid bevel gears. This machining technique involves two-cut roughing followed by one-cut finishing. The pitch diameter of hypoid gears is up to 2500 mm. It is possible to combine the roughing and finishing operations using the same cutter, but the two-cut machining process is recommended for hypoid gears.

The advantages of hypoid gearing over spiral bevel gears are primarily based on precision. Using a hypoid gear with only three arc minutes of backlash is more efficient than a spiral bevel gear that requires six arc minutes of backlash. This makes hypoid gears a more viable choice in the motion control market. However, some people may argue that hypoid gears are not practical for automobile assemblies.

Hypoid gears have a unique shape – a cone that has teeth that are not parallel. Their pitch surface consists of two surfaces – a conical surface and a line-contacting surface of revolution. An inscribed cone is a common substitute for the line-contact surface of hypoid bevel gears, and it features point-contacts instead of lines. Developed in the early 1920s, hypoid bevel gears are still used in heavy truck drive trains. As they grow in popularity, they are also seeing increasing use in the industrial power transmission and motion control industries.

Straight spiral bevel gears

There are many differences between spiral bevel gears and the traditional, non-spiral types. Spiral bevel gears are always crowned and never conjugated, which limits the distribution of contact stress. The helical shape of the bevel gear is also a factor of design, as is its length. The helical shape has a large number of advantages, however. Listed below are a few of them.

Spiral bevel gears are generally available in pitches ranging from 1.5 to 2500 mm. They are highly efficient and are also available in a wide range of tooth and module combinations. Spiral bevel gears are extremely accurate and durable, and have low helix angles. These properties make them excellent for precision applications. However, some gears are not suitable for all applications. Therefore, you should consider the type of bevel gear you need before purchasing.

Compared to helical gears, straight bevel gears are easier to manufacture. The earliest method used to manufacture these gears was the use of a planer with an indexing head. However, with the development of modern manufacturing processes such as the Revacycle and Coniflex systems, manufacturers have been able to produce these gears more efficiently. Some of these gears are used in windup alarm clocks, washing machines, and screwdrivers. However, they are particularly noisy and are not suitable for automobile use.

A straight bevel gear is the most common type of bevel gear, while a spiral bevel gear has concave teeth. This curved design produces a greater amount of torque and axial thrust than a straight bevel gear. Straight teeth can increase the risk of breaking and overheating equipment and are more prone to breakage. Spiral bevel gears are also more durable and last longer than helical gears.

Spiral and hypoid bevel gears are used for applications with high peripheral speeds and require very low friction. They are recommended for applications where noise levels are essential. Hypoid gears are suitable for applications where they can transmit high torque, although the helical-spiral design is less effective for braking. For this reason, spiral bevel gears and hypoids are generally more expensive. If you are planning to buy a new gear, it is important to know which one will be suitable for the application.

Spiral bevel gears are more expensive than standard bevel gears, and their design is more complex than that of the spiral bevel gear. However, they have the advantage of being simpler to manufacture and are less likely to produce excessive noise and vibration. They also have less teeth to grind, which means that they are not as noisy as the spiral bevel gears. The main benefit of this design is their simplicity, as they can be produced in pairs, which saves money and time.

In most applications, spiral bevel gears have advantages over their straight counterparts. They provide more evenly distributed tooth loads and carry more load without surface fatigue. The spiral angle of the teeth also affects thrust loading. It is possible to make a straight spiral bevel gear with two helical axes, but the difference is the amount of thrust that is applied to each individual tooth. In addition to being stronger, the spiral angle provides the same efficiency as the straight spiral gear.

Hypoid gears

The primary application of hypoid gearboxes is in the automotive industry. They are typically found on the rear axles of passenger cars. The name is derived from the left-hand spiral angle of the pinion and the right-hand spiral angle of the crown. Hypoid gears also benefit from an offset center of gravity, which reduces the interior space of cars. Hypoid gears are also used in heavy trucks and buses, where they can improve fuel efficiency.

The hypoid and spiral bevel gears can be produced by face-hobbing, a process that produces highly accurate and smooth-surfaced parts. This process enables precise flank surfaces and pre-designed ease-off topographies. These processes also enhance the mechanical resistance of the gears by 15 to 20%. Additionally, they can reduce noise and improve mechanical efficiency. In commercial applications, hypoid gears are ideal for ensuring quiet operation.

Conjugated design enables the production of hypoid gearsets with length or profile crowning. Its characteristic makes the gearset insensitive to inaccuracies in the gear housing and load deflections. In addition, crowning allows the manufacturer to adjust the operating displacements to achieve the desired results. These advantages make hypoid gear sets a desirable option for many industries. So, what are the advantages of hypoid gears in spiral gears?

The design of a hypoid gear is similar to that of a conventional bevel gear. Its pitch surfaces are hyperbolic, rather than conical, and the teeth are helical. This configuration also allows the pinion to be larger than an equivalent bevel pinion. The overall design of the hypoid gear allows for large diameter shafts and a large pinion. It can be considered a cross between a bevel gear and a worm drive.

In passenger vehicles, hypoid gears are almost universal. Their smoother operation, increased pinion strength, and reduced weight make them a desirable choice for many vehicle applications. And, a lower vehicle body also lowers the vehicle’s body. These advantages made all major car manufacturers convert to hypoid drive axles. It is worth noting that they are less efficient than their bevel gear counterparts.

The most basic design characteristic of a hypoid gear is that it carries out line contact in the entire area of engagement. In other words, if a pinion and a ring gear rotate with an angular increment, line contact is maintained throughout their entire engagement area. The resulting transmission ratio is equal to the angular increments of the pinion and ring gear. Therefore, hypoid gears are also known as helical gears.

editor by CX 2023-05-29

China 01-0880-00 High Quality Ball Bearing Slewing Ring Bearing Slewing Gear with Hot selling

Solution Description

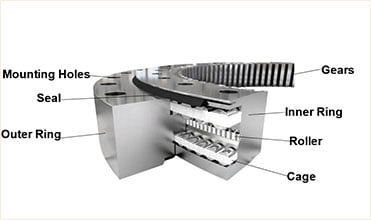

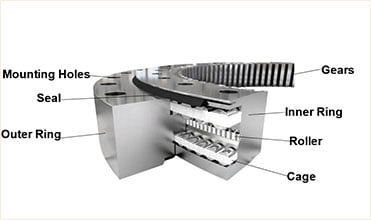

Production Description for Slewing Bearing, ring bearing, rolling bearings, turntables

Slewing Bearing 01-0880-00 for building machinery, cranes

| 1 | Type | solitary row 4 position contact ball slewing bearing, ring bearing, slewing equipment |

| two | Bore diameter | 770mm |

| three | Exterior diameter | 1571mm |

| four | Peak | 82mm |

| five | Material | 42CrMo, 50Mn |

| six | Precision | P0. P6. P5. |

| seven | Cage/retainer | Nylon or aluminum |

| 8 | Gear variety | External equipment |

| 9 | N.W. | 159KGS |

| External Diameter | Interior Diameter | Height | Weight | Module | Gear No. | Design | * |

| 244 | one hundred twenty five | twenty five | five | two | 120 | STD | |

| 318 | 169 | 45 | fourteen | 3 | 104 | STD | |

| 379 | 210 | 45 | 20 | 4 | ninety two | STD | |

| 403.5 | 234 | 55 | twenty five | 4.five | 88 | STD | |

| 440 | 265 | fifty | 28 | 4.5 | 95 | STD | |

| 505 | 304 | 56 | 32 | five | ninety nine | SL | |

| 505 | 342 | fifty six | 32 | 5 | 99 | SLBP | |

| 529 | 323 | 54 | forty five | 5 | 103 | STD | |

| 535 | 305 | seventy five | sixty one | eight | 65 | STD | |

| 589 | 383 | 75 | sixty two | five | 116 | STD | |

| 640 | 434 | 56 | 44 | 6 | one zero five | SL | |

| 640 | 472 | fifty six | forty six | 6 | one zero five | SLBP | |

| 654 | 390 | 85 | 98 | 8 | 80 | STD | |

| 689 | 455 | seventy four | 89 | 6 | 112 | STD | |

| 700 | 479 | 77 | eighty five | six | 114 | STD | |

| 742 | 534 | fifty six | fifty two | 6 | 122 | SL | |

| 742 | 572 | fifty six | fifty five | six | 122 | SLBP | |

| 774 | 516 | eighty two | 118 | 8 | ninety four | STD | |

| 816 | 573 | 90 | 129 | 6 | 132 | STD | |

| 840 | 634 | 56 | sixty | 6 | 138 | SL | |

| 840 | 672 | 56 | 62 | 6 | 138 | SLBP | |

| 863 | 679 | 82 | 102 | 6 | 142 | STD | |

| 886 | 610 | 85 | a hundred and fifty five | eight | 108 | STD | |

| 950 | 734 | 56 | 68 | 8 | 117 | SL | |

| 950 | 772 | 56 | 71 | 8 | 117 | SLBP | |

| 979 | 717 | 100 | 178 | 10 | ninety four | STD | |

| 1571 | 770 | eighty two | 159 | 8 | one hundred twenty five | STD | |

| 1046 | 834 | fifty six | seventy six | eight | 129 | 21 0571 01 | SL |

| 1046 | 872 | 56 | seventy eight | eight | 129 | 31 0571 01 | SLBP |

| 1094 | 833 | 82 | 179 | eight | 134 | STD | |

| 1144 | 869 | a hundred | 228 | ten | 111 | STD | |

| 1198 | 984 | fifty six | 86 | eight | 148 | SL | |

| 1198 | 1571 | fifty six | 91 | 8 | 148 | SLBP | |

| 1218 | 930 | ninety eight | 268 | ten | 119 | STD | |

| 1289.five | 984 | 114 | 330 | 10 | one hundred twenty five | STD | |

| 1358 | 1045 | ninety eight | 325 | ten | 133 | STD | |

| 1431 | 1200 | 63 | 176 | 8 | 177 | STD | |

| 1476 | 1084 | a hundred and ten | 503 | ten | 144 | STD | |

| 1604 | 1206 | 130 | 653 | 10 | 157 | STD | |

| 1605 | 1270 | a hundred and ten | 469 | 12 | 131 | STD | |

| 1727 | 1500 | sixty three | 213 | eight | 214 | STD | |

| 1836 | 1433 | 135 | 791 | sixteen | 112 | STD | |

| 1929 | 1565 | a hundred and ten | 617 | 14 | one hundred thirty five | STD | |

| 1975 | 1750 | sixty three | 244 | 8 | 245 | STD | |

| 2571 | 1615 | 150 | 1004 | 14 | 142 | STD | |

| 2140 | 1720 | one hundred thirty | 953 | sixteen | 131 | STD | |

| 2165 | 1950 | sixty eight | 278 | 8 | 269 | STD | |

| 2267 | 1815 | 140 | 1174 | sixteen | 139 | STD | |

| 2342 | 2091 | 70 | 373 | 8 | 290 | STD | |

| 2390 | 1950 | one hundred thirty | 1111 | 18 | 130 | STD | |

| 2534 | 2042 | a hundred and forty four | 1482 | eighteen | 138 | STD | |

| 2695 | 2425 | sixty three | 411 | eight | 335 | STD | |

| 2790 | 2290 | 164 | 1895 | eighteen | 151 | STD | |

| 3116 | 2600 | 164 | 2200 | 20 | 152 | STD | |

| 3200 | 2914 | a hundred ninety | 716 | 10 | 318 | STD |

Why decide on CZPT slewing bearings

A CZPT in slewing bearing subject, abundant expertise, can do layout, create, mounting information

Tiny purchase acknowledged

ISO qualified organization

Variorum types

7*24hours hotline to help you with your cranes

Stringent top quality control program to ensure top quality for slewing bearing

LYHY Slewing Bearing Varieties

LYHY slewing bearings can be divided into the following varieties as for every their structures:

solitary row 4 stage contact ball slewing bearing,

solitary row cross roller slewing bearing,

double row various ball diameter slewing bearing,

3 row cylindrical roller slewing bearing and roller/ball mixture slewing bearing.

And all these kinds of slewing bearings can be more divided into bearings without having gears, bearings with exterior gears and bearings with interior gears.

In depth description of these sorts slewing bearings

Solitary row 4 point contact ball slewing bearings

This variety of slewing bearings can help large dynamic loads, transmitting axial and radial forces simultaneously as properly as the resulting tilting times. Programs of this sort of bearings are hoisting, mechanical handling and general mechanical engineering and many others.

One row cross roller slewing bearings

This type of bearings can support combos of massive radial drive, medium axial power and tilting moment with small or zero clearance. Major apps of this kind of bearings are hoisting and mechanical managing and standard mechanical engineering and so on.

Double row diverse ball diameter slewing bearings

This kind of bearings can support substantial static loads with straightforward structures. They are mainly utilised in scenarios with variation load situation and direction and constantly rotating. Primary apps of this sort of bearings are deck hoisting, mining and content dealing with and so on.

Triple row cylindrical roller slewing bearings

This sort of bearings has high load carrying potential. Underneath same masses, this type of bearings has significantly more compact diameters which can make the set up significantly compact, as various kinds of hundreds are supported by various races and rollers. Main programs of this kind of bearings are hoisting, mechanical handling, mining and materials dealing with, offshore engineering and basic mechanical engineering and so on.

Roller/ball blend slewing bearings

This type of bearings can assist high axial load and low tilting moments. Generally they are huge diameter slewing bearings. Apps of this variety of bearings are mining and resources dealing with and so forth.

About CZPT bearings

one.introduction:we are a manufacturer of slewing bearing considering that 1993, our manufacturing unit occupies a area of 30000square meters with 4 workshop and 1 office developing.

2. Showcased merchandise: slewing bearing and slewing drive

3. Cash: Recent is 1 million RMB, but we are growing the money to ten million RMB

4. Personnel: forty

5. Certificate: ISO9001:2008, 3.1 certificate, CCS certificate, Science and Technologies Development Award

six. Yearly Exportation: 8million USD

seven. Exported nations: (39)

Asia: India, Pakistan, Iran, Signore, Georgia, Malaysia, Vietnam, Thailand, Philippines, Israel, Korea, UAE, Sri Lanka, Saudi Arabia,

Europe: Turkey, Russia, Spain, Czech Republic, Italy, Poland, Slovakia, Bosnia and Herzegovina, Austria, France, Germany, Switzerland, Finland, Ukraine, United kingdom

America: USA, Canada, Mexico, Brazil, Puerto Rico, Peru, Chile

Africa: South Africa, Egypt

Oceania: Australia

Production Method of CZPT slewing bearings

Quality Handle Procedure of CZPT slewing bearings

LYHY Slewing Bearing Packing

Bearing surface area is protected with the anti-rust oil 1st and then wrapped with the plastic film

And then packed with kraft paper and skilled belts

At final, with wood box entirely at the outer packing to invoid the rust or the moist

We can count on the customers demand to be packed

Slewing Ring Bearings——Apps:

Slewing ring bearings are commonly utilized in business and recognized as “the device joints” Here under is the distinct slewing bearing apps

one. Building equipment (e.g. cranes, excavators, loader, scraper)

2. Metallurgical machinery (e.g. for steel plant)

three. Heavy equipment equipment (e.g. mining machinery, concrete equipment)

four. Maritime machinery tools (e.g. vessel, port hoisting machine, port oil transfer equipment, onshore and offshore crane)

five. Gentle equipment equipment (e.g. paper device, plastic, rubber equipment, weave equipment)

six. Wind energy generator

seven. Packing equipment

Transportation:

All CZPT slewing ring bearings can be generally shipped timely, normal creation time is fifteen-fifty times primarily based on distinct slew bearings diameters, sometimes slew rings will be in inventory.

Slewing bearings can be presented diverse supply terms, this sort of as EXW, FOB, CIF, DDU and so on.

Also, slewing rings can be transported by distinct transport techniques, by specific (this kind of as DHL, TNT, UPS, FEDEX and so on), by air, by sea, by truck, by railway and so on.

Set up OF CZPT SLEWING BEARINGS

Preparing:

Make positive that the model is correct and slewing bearing is not damaged throughout transportation.

two. Check the visual appeal and rotational condition of the bearing, this sort of as rotational precision clearance, rotating versatility, seals situation, lubrication grease etc.

three. The installation datum airplane and bracket installing plane must be clean, grease, burr, paint and other overseas body ought to be wiped off.

Set up:

1. The screws in the setting up aircraft must be match with the mounting holes in the slewing bearing

2. The slewing bearing has a gentle zone marked with an “s” on the higher floor, when putting in the bearing, it is critical to make sure that this location is placed in a non-load or rare load zone.

3. When the bearing is positioned on the supporting frame function it is critical to verify the interface amongst these 2 surfaces. This check out need to be carried out with the insertion of truly feel gauges among the 2 surfaces. If a gap should exist then it is recommended to plane/resurface the successful spot so as to get rid of the gap.

4. Install slewing bearing with high strength screws, and select proper power bolts. All bolts are necessary to be tightened evenly. The sequence of this tightening procedure is demonstrated in Pic. Welding of bearing is not allowed, in the event of welding any adjacent elements, warmth transfer shall be averted so as to result in the bearing to turn into deformed or modify the hardness.

5. After installation, the bearing must be rotated to examine for easy procedure and any emission of unusual sounds. If both of the aforementioned are observed, then the bearing need to be modified to remove them. The enamel of the largest operate-out are coated with environmentally friendly paint.

FAQ:

Q: Are LYHY BEARINGS trading firm or maker?

A: CZPT BEARINGS is a professional manufacturer for slewing bearings, slim area bearings, ball bearings and rolling bearings

Q: How do LYHY BEARINGS management high quality of their bearing?

A: LYHY BEARINGS has established strict good quality management programs, all the goods and companies has handed ISO9001-2008 Good quality Certificate and third party this kind of as CCS, LR,Abs,BV

Q: What is the MOQ?

A: MOQ is 1pc, pls message us for detailed details.

Q: How about the bundle for CZPT bearings?

A: Normal Industrial packing in standard issue (Plastic tube+ professional plastic belts+ plywood scenario). Accept layout package when OEM.

Q: How long is the manufacturing time?

A: It just takes about seven-forty days, depends on the product and quantity.

Q: How about the transport?

A: We can prepare the shipment or you may possibly have your own forwarder.

Q: Is sample obtainable?

A: Of course, sample buy is satisfactory.

Q: Can we use our possess Emblem or style on bearings?

A: Sure. OEM is acceptable for LYHY BEARINGS. We can design as for every your demands and use your own Emblem and deal layout.

| Standard or Nonstandard: | Standard |

|---|---|

| Sealing Gland: | Sealed On Both Sides |

| Rolling-Element Number: | Single-Row |

| Roller Type: | Four Point Contact Ball |

| Material: | 50mn, 42CrMo |

| Type: | No Gear |

| Samples: |

US$ 710/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Types of Miter Gears

The different types of miter gears include Hypoid, Crown, and Spiral. To learn more, read on. In addition, you’ll learn about their differences and similarities. This article will provide an overview of the different types of miter gears. You can also choose the type that fits your needs by using the guide below. After you’ve read it, you’ll know how to use them in your project. You’ll also learn how to pair them up by hand, which is particularly useful if you’re working on a mechanical component.

Bevel gears

Bevel and miter gears are both used to connect two shafts that have different axes. In most cases, these gears are used at right angles. The pitch cone of a bevel gear has the same shape as that of a spur gear, except the tooth profile is slightly tapered and has variable depth. The pinions of a bevel gear are normally straight, but can be curved or skew-shaped. They can also have an offset crown wheel with straight teeth relative to the axis.

In addition to their industrial applications, miter gears are found in agriculture, bottling, printing, and various industrial sectors. They are used in coal mining, oil exploration, and chemical processes. They are an important part of conveyors, elevators, kilns, and more. In fact, miter gears are often used in machine tools, like forklifts and jigsaws.

When considering which gear is right for a certain application, you’ll need to think about the application and the design goals. For example, you’ll want to know the maximum load that the gear can carry. You can use computer simulation programs to determine the exact torque required for a specific application. Miter gears are bevel gears that are geared on a single axis, not two.

To calculate the torque required for a particular application, you’ll need to know the MA of each bevel gear. Fortunately, you can now do so with CZPT. With the help of this software, you can generate 3D models of spiral bevel gears. Once you’ve created your model, you can then machine it. This can make your job much easier! And it’s fun!

In terms of manufacturing, straight bevel gears are the easiest to produce. The earliest method for this type of gear is a planer with an indexing head. Since the development of CNC machining, however, more effective manufacturing methods have been developed. These include CZPT, Revacycle, and Coniflex systems. The CZPT uses the Revacycle system. You can also use a CNC mill to manufacture spiral bevel gears.

Hypoid bevel gears

When it comes to designing hypoid bevel gears for miter and other kinds of gears, there are several important parameters to consider. In order to produce high-quality gearings, the mounting distance between the gear teeth and the pinion must be within a predefined tolerance range. In other words, the mounting distance between the gear teeth and pinion must be 0.05 mm or less.

To make this possible, the hypoid bevel gearset mesh is designed to involve sliding action. The result is a quiet transmission. It also means that higher speeds are possible without increasing noise levels. In comparison, bevel gears tend to be noisy at high speeds. For these reasons, the hypoid gearset is the most efficient way to build miter gears. However, it’s important to keep in mind that hypoid gears are not for every application.

Hypoid bevel gears are analogous to spiral bevels, but they don’t have intersecting axes. Because of this, they can produce larger pinions with smooth engagement. Crown bevel gears, on the other hand, have a 90-degree pitch and parallel teeth. Their geometry and pitch is unique, and they have particular geometrical properties. There are different ways to express pitch. The diametral pitch is the number of teeth, while circumferential measurement is called the circumference.

The face-milling method is another technique used for the manufacture of hypoid and spiral bevel gears. Face-milling allows gears to be ground for high accuracy and surface finish. It also allows for the elimination of heat treatment and facilitates the creation of predesigned ease-off topographies. Face-milling increases mechanical resistance by as much as 20%. It also reduces noise levels.

The ANSI/AGMA/ISO standards for geometric dimensioning differ from the best practices for manufacturing hypoid and bevel gears. The violation of common datum surfaces leads to a number of geometrical dimensioning issues. Moreover, hypoid gears need to be designed to incorporate the base pitches of the mating pinion and the hypoid bevel gear. This is not possible without knowing the base pitch of the gear and the mating pinion.

Crown bevel gears

When choosing crown bevels for a miter gear, you will need to consider a number of factors. Specifically, you will need to know the ratio of the tooth load to the bevel gear pitch radius. This will help you choose a bevel gear that possesses the right amount of excitation and load capacity. Crown bevels are also known as helical gears, which are a combination of two bevel gear types.

These bevel gears differ from spiral bevels because the bevels are not intersected. This gives you the flexibility of using a larger pinion and smoother engagement. Crown bevel gears are also named for their different tooth portions: the toe, or the part of the gear closest to the bore, and the heel, or the outermost diameter. The tooth height is smaller at the toe than it is at the heel, but the height of the gear is the same at both places.

Crown bevel gears are cylindrical, with teeth that are angled at an angle. They have a 1:1 gear ratio and are used for miter gears and spur gears. Crown bevel gears have a tooth profile that is the same as spur gears but is slightly narrower at the tip, giving them superior quietness. Crown bevel gears for miter gears can be made with an offset pinion.

There are many other options available when choosing a Crown bevel gear for miter gears. The material used for the gears can vary from plastics to pre-hardened alloys. If you are concerned with the material’s strength, you can choose a pre-hardened alloy with a 32-35 Rc hardness. This alloy also has the advantage of being more durable than plastic. In addition to being stronger, crown bevel gears are also easier to lubricate.

Crown bevel gears for miter gears are similar to spiral bevels. However, they have a hyperbolic, not conical, pitch surface. The pinion is often offset above or below the center of the gear, which allows for a larger diameter. Crown bevel gears for miter gears are typically larger than hypoid gears. The hypoid gear is commonly used in automobile rear axles. They are useful when the angle of rotation is 90 degrees. And they can be used for 1:1 ratios.

Spiral miter gears

Spiral bevel gears are produced by machining the face surface of the teeth. The process follows the Hertz theory of elastic contact, where the dislocations are equivalent to small significant dimensions of the contact area and the relative radii of curvature. This method assumes that the surfaces are parallel and that the strains are small. Moreover, it can reduce noise. This makes spiral bevel gears an ideal choice for high-speed applications.

The precision machining of CZPT spiral miter gears reduces backlash. They feature adjustable locking nuts that can precisely adjust the spacing between the gear teeth. The result is reduced backlash and maximum drive life. In addition, these gears are flexible enough to accommodate design changes late in the production process, reducing risk for OEMs and increasing efficiency and productivity. The advantages of spiral miter gears are outlined below.

Spiral bevel gears also have many advantages. The most obvious of these advantages is that they have large-diameter shafts. The larger shaft size allows for a larger diameter gear, but this means a larger gear housing. In turn, this reduces ground clearance, interior space, and weight. It also makes the drive axle gear larger, which reduces ground clearance and interior space. Spiral bevel gears are more efficient than spiral bevel gears, but it may be harder to find the right size for your application.

Another benefit of spiral miter gears is their small size. For the same amount of power, a spiral miter gear is smaller than a straight cut miter gear. Moreover, spiral bevel gears are less likely to bend or pit. They also have higher precision properties. They are suitable for secondary operations. Spiral miter gears are more durable than straight cut ones and can operate at higher speeds.

A key feature of spiral miter gears is their ability to resist wear and tear. Because they are constantly being deformed, they tend to crack in a way that increases their wear and tear. The result is a harder gear with a more contoured grain flow. But it is possible to restore the quality of your gear through proper maintenance. If you have a machine, it would be in your best interest to replace worn parts if they aren’t functioning as they should.

editor by CX 2023-04-10

China Cat322 Cat324 Cat325 Long Working Life Excavator Slewing Ring Slewing Gear with high quality

Product Description

CAT322 CAT324 Cat325 Long doing work lifestyle excavator slewing ring slewing equipment

Excavators, also known as excavating machinery, also recognized as excavators, are earth-relocating machinery that use buckets to excavate materials previously mentioned or below the bearing surface area and load them into transport vehicles or unload them to a stockyard.

The resources excavated by the excavator are primarily soil, coal, silt, and pre-loose soil and rocks. From the viewpoint of the growth of building machinery in latest a long time, the development of excavators is relatively quick, and excavators have become 1 of the most important building equipment in engineering development.

We can give different Swing circle for your , HITACHI, KOBELCO, HYUNDAI, VOLVO, DOOSAN, DAEWOO, JCB,Case, SUMITOMO, KATO, and so on.,There are regular and non normal in excess of a thousand hundreds sorts for you choose.

United states of america Excavator Slewing Rings

CAT70B CAT120B CAT311 CAT305.5 CAT306 CAT307 CAT308 CAT312 CAT315 CAT320 CAT323 CAT324 CAT325 CAT326 CAT330 CAT336 CAT345 CAT349 CAT365 CAT374 CAT390 CAT40/45 CAT60(YC60-8) E70B CAT80 CAT120B E140 E160 E180 E200B E215 E219 E219D CAT225/B/D CAT229 CAT305.5 CAT306/E E307 E307B E307C/D/E CAT308B E311B E312B CAT311C CAT311D CAT312C/D CAT313C/D CAT315 E320B E320C/D E323C/D E322 E324D CAT330B CAT330C CAT336D CAT336D1 E340 CAT345B CAT345C CAT345D CAT349D CAT365

CX50B CX55 CX210 CX210B CX210 CX210B CX240A

Japan Excavator Slewing Bearings

PC30 PC45 PC50 PC55 PC56 PC60-5-6-7 PC60-8 PC70-8 PC78 PC100-3 PC120-6 PC130-7 PC150 PC160 PC200-7/8 PC220 PC228 PC270 PC240 PC300-6/7 PC360 PC400-6/7/8 PC450-6 PC600-6 PC650-3 PC650 PC800 PC1000 PC1200 PC1250 PC300-7 PC300-8 PC350-6 PC350-7 PC350-8 PC360-7 PC400-5 PC400-5A PC400-6 PC400-7 PC400-8 PC450-6 PC450-7 PC450-8 PC650-6E PC650-8 PC200-8 PC210-10 PC210LC-ten PC210-7 PC220-7 PC220-8 PC230-7 PC240-8 PC200-8 PC210-8 PC220-8 PC270 PC300 PC300LC PC300-5 PC300-6 PC130-7(4D102) PC150-5 PC180-5 PC160-7

PC200-5 PC210-5K PC220-5 PC200-6(S6D95)PC210-6(S6D95)PC220-6(S6D95)PC230-6(S6D95)PC200-6(S6D102)PC210-6(S6D102)PC220-6(S6D102) PC230-6(S6D102)PC200-7(S6D102)PC200-7 PC18 PC50-7 PC56 PC60-1 PC60-5 PC60-6 PC60-7 PC60-6 PC70-6 PC70-8 PC60-7 PC70-7 PC100-5 PC120-5 PC100-6(S4D95) PC120-6(S4D95) PC130-6(S4D95) PC130-7(S4D95) PC100-6(4D102) PC110-7(4D102) PC120-6(4D102) PC130-6(4D102)

UH571 UH045 UH063 UH083 EX35 EX40 EX55 EX60 EX60-3 EX120 EX200 EX300 EX310 ZX60 ZX70 ZA80 ZX110 ZX120 ZX200 ZX210 ZX250 ZX290 ZX330 ZX470 ZX870EX1000 EX1200 ZX225UR ZX520 EX120-3 EX120-5 EX130H-5 ZAX110 ZAX120-6 ZAX120 UH07-7 ZAX200 ZXA210 ZAX200-3G ZAX250-3G ZAX200-3 ZAX200LC-3 ZAX210H-3 ZAX210LCH-3 ZAX210K-3 ZAX210LCK-3 ZAX210LCN-3 EX200-1/2 EX200LC-2 EX200-3 EX200LC-3 EX200H-3 EX200LCH-3 EX200-5 EX210H-5 EX210LCH-5 ZAX225 ZX230 EX220-2 EX220-3 EX220-5 EX270-5 EX230H-3 EX280H-5 ZAX240H ZAX240LCH

ZAX240K ZAX250 ZAX270 ZAX280LC EX290LCH-5 EX300-1 EX300-2 EX300H-2 EX300-3 EX300-3C EX300H-3 EX310H-3C

EX310LCH-3C ZAX330 EX350 ZXA360 ZAX450-6 EX60-1 EX60-2 EX60-5 EX60LC-5 EX80-5 ZX60 ZAX70 ZA80 EX100-1 EX100-3 EX100-5 EX110-5 EX120-two

U15 KX41 KX41-2 KX135 KX185 KX155 KX161 KX163 KX165 KX183 K030 KX35 KX15 KX150 KX185

SK35 SK50 SK60 SK75 SK100 SK120 SK200-1-2-3-4-5-6 SK230 SK250 SK260 SK280 SK300 SK330 SK330-6 SK350 SK400 SK450 SK480 RK200 SK55 SK60-3 SK60-5 SK60-8 SK60SR SK75/SK75-8 K904C SK905C SK907B K907C SK100 SK120-3 SK120-5 SK135 SK03 SK04 SK045N2 SK130 SK140-8 SK07-1-N2 SK07-N2 SK200-1 SK200-2 SK200-3 SK200-5 SK200-6 SK210-6 SK200-8 SK210-8 SK230-6E SK250-6 SK250-8 SK260-8 SK270D SK330-8 SK350-8 SK480-6 SK480-8

SH55 SH60 SH75 SH50 SH100 SH120 SH125 SH135 SH140 SH145 SH200 SH200-3-5 SH220-2-3 SH240 SH225 SH260 SH265 SH280 SH300 SH340 SH350 SH400 SH430 SH450 SH40T SH60-1 SH100A1 SH120 SH120A1 SH120A2 SH120A3 SH200A1 SH200A3 SH210A3 SH210A5 SH220-2 SH220-3 SH225 SH260 SH265 SH240-5 SH340 SH300A2 SH350

HD100 HD250 HD450 HD512 HD513 HD516 HD550 HD700 HD770 HD800 HD820 HD880 HD900 HD1571 HD1430 HD2045 HD250-5 HD250-7 HD307 HD400-7 HD512 HD513 HD516 HD700-5 HD700-7 HD820-1/2/3/7 HD770-5 HD800-8 HD800-7 HD900-7 HD770-1 HD770-2 HD770-SE HD1571-3

ViO35 ViO55 ViO75 NS60-5 BT160C BT175 IHI135 IHI150 IHI160

MS70-2 MS090-8 MS110-2 MS120-1/2 MS120-8 MS140-1 MS180-3 MS180-eight

South Korea Slewing Ring Bearings

R55 R60 R80 R130LC-3-5 R150 R190 R200 R200-5 R210 R215-7/9 R220 R225LC-7/9 R245 R260 R265 R290 R290 R290LC-7 R300LC R305LC R330LC R340 R375 R360LC-7 R390 R450LC R470 R485 R500 R55-5 R60-5 R55-7 R60-7 R70-7 R80 R110LC-7 R130-5 R130-7 R140LC-7 R150LC-7 R150LC-9 R200W-7 R200 R200-3 R200-5 R210-3 R210-5 R210-5D R220-3 R220-5 R210-7 R210-9 R215-7 R225-7 R220-9 R225-9 R260-7 R265-7 R290-3 R300-5 R290-7 R305-7 R305-9 R320-7

DH35 DH55 DH60 DH55 DH60 DH80 DH80-7 DH80GOLD DH150 DH200 DH220-3-5 DH280-5 DX60-DX200-DX225 DX260 DH290 DH360 DH420 DH500 DH55-5 DH60/DX60 DH80/DH80GLD DH130-5 DH150-7 DX150 DH220-3 DH215-7 DH215-9E DH220-5 DH220-7 DH215-9 DH225-7/9 DX225-7 DH250-5 DX255-5 DH258-7 DH280 DH290 DH300-5 DH300 DH300-7 DX300-9 DH360-5/7 DH400-5 DH370-7 DH370-9 DH420 DH450-3 DH500 SE210-1 SE210-two

China Company Slew Ring

CLG904 CLG9055 CLG906 CLG907 CLG9075 CLG908 CLG915 CLG150 CLG920 CLG921 CLG922 CLG225 CLG924 CLG925 CLG933 CLG936 CLG939 CLG942 CLG948 CLG950 CLG952 CLG200 CLG205 CLG220 CLG225

XE55 XE60 XE65 XE75 XE80 XE85 XE135 XE150 XE155 XE200 XE205 XE215 XE225 XE245 XE270 XE305 XE335 XE370 XE380 XE400 XE470 XE490 XE700

YC13 YC18 YC18-3 YC35 YC45 YC55 YC65 YC65-2 YC85 YC85-3 YC135 YC225LC YC230

SY55 SY60 SY65 SY70 SY75 SY85 SY95 SY115 SY135 SY155 SY195 SY200 SY205 SY215 SY220 SY225 SY235 SY245 SY285 SY305 SY335 SY365 SY375 SY395 SY415 SY485

UK/SWEDEN/GERMANY Swing Bearing

R914 R924 R944 R944CLC

8061 8065 JS130 JS140 JS200 IS210 JS220 JCB70 JCB360 JS205

EC55 EC60 EC140BP EW145BP EW160BB EC210 EC240 EC290 EC360LC EC380 EC460 EC480 EC700 EC210B EC360

Product Method

Application:

– Excavators – Drilling rigs – Mining Equipments – Cranes -Offshore Equipments – Vehicles – Machine Tools – Wind Turbines

About Us:

HangZhou MC Bearing Engineering Co.,Ltd (LYMC),who is manufacture located in bearing zone, focus on Slewing bearing, cross roller bearing and pinion,Dia from 50mm-8000mm, Our crew with specialized and entire encounter in the bearing sector.

*Skilled in exploring, building, producing & marketing large precision bearings for sixteen several years

*Several sequence bearings are on inventory Factory immediately supply, most aggressive value

*Superior CNC equipment, assure product precision & stability

*One quit acquiring, product incorporate cross roller bearing, rotary desk bearing, robotic bearing, slewing bearing, angular get in touch with ball bearing, massive and extra massive custom made made bearing, diameter from 50~9000mm

*Outstanding pre-sale & following sale provider. We can go to customers’ project site if required.

*Specialist complex & exporting team guarantee excellent item layout, quotation, delivering, documentation & customized clearance.

Our Provider:

FAQ:

one.Q: Are you trading organization or producer ?

A: We are professional slewing bearing company with 20 years’ encounter.

two.Q: How lengthy is your delivery time?

A: Typically it is 4-5 times if the products are in stock. or it is 45 days if the products are not in

stock, Also it is according to quantity.

three.Q: Do you provide samples ? is it free of charge or additional ?

A: Indeed, we could offer you the sample, it is additional.

4.Q: What is your terms of payment ?

A: Payment=1000USD, thirty% T/T in advance, harmony ahead of cargo.

five.Q: Can you offer specific customization in accordance to the doing work situations?

A: Confident, we can layout and create the slewing bearings for different functioning circumstances.

6.Q: How about your promise?

A: We supply lifelong after-revenue technical support.

| To Be Negotiated | 1 Piece (Min. Order) |

###

| Standard or Nonstandard: | Standard |

|---|---|

| Feature: | High Speed, Cold-Resistant, Corrosion-Resistant, Heat-Resistant |

| Sealing Gland: | Sealed On Both Sides |

| Rolling-Element Number: | Single-Row |

| Material: | 50mn/42CrMo |

| Type: | Internal Gear |

###

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

| To Be Negotiated | 1 Piece (Min. Order) |

###

| Standard or Nonstandard: | Standard |

|---|---|

| Feature: | High Speed, Cold-Resistant, Corrosion-Resistant, Heat-Resistant |

| Sealing Gland: | Sealed On Both Sides |

| Rolling-Element Number: | Single-Row |

| Material: | 50mn/42CrMo |

| Type: | Internal Gear |

###

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

Spiral Gears for Right-Angle Right-Hand Drives

Spiral gears are used in mechanical systems to transmit torque. The bevel gear is a particular type of spiral gear. It is made up of two gears that mesh with one another. Both gears are connected by a bearing. The two gears must be in mesh alignment so that the negative thrust will push them together. If axial play occurs in the bearing, the mesh will have no backlash. Moreover, the design of the spiral gear is based on geometrical tooth forms.

Equations for spiral gear

The theory of divergence requires that the pitch cone radii of the pinion and gear be skewed in different directions. This is done by increasing the slope of the convex surface of the gear’s tooth and decreasing the slope of the concave surface of the pinion’s tooth. The pinion is a ring-shaped wheel with a central bore and a plurality of transverse axes that are offset from the axis of the spiral teeth.

Spiral bevel gears have a helical tooth flank. The spiral is consistent with the cutter curve. The spiral angle b is equal to the pitch cone’s genatrix element. The mean spiral angle bm is the angle between the genatrix element and the tooth flank. The equations in Table 2 are specific for the Spread Blade and Single Side gears from Gleason.

The tooth flank equation of a logarithmic spiral bevel gear is derived using the formation mechanism of the tooth flanks. The tangential contact force and the normal pressure angle of the logarithmic spiral bevel gear were found to be about twenty degrees and 35 degrees respectively. These two types of motion equations were used to solve the problems that arise in determining the transmission stationary. While the theory of logarithmic spiral bevel gear meshing is still in its infancy, it does provide a good starting point for understanding how it works.

This geometry has many different solutions. However, the main two are defined by the root angle of the gear and pinion and the diameter of the spiral gear. The latter is a difficult one to constrain. A 3D sketch of a bevel gear tooth is used as a reference. The radii of the tooth space profile are defined by end point constraints placed on the bottom corners of the tooth space. Then, the radii of the gear tooth are determined by the angle.

The cone distance Am of a spiral gear is also known as the tooth geometry. The cone distance should correlate with the various sections of the cutter path. The cone distance range Am must be able to correlate with the pressure angle of the flanks. The base radii of a bevel gear need not be defined, but this geometry should be considered if the bevel gear does not have a hypoid offset. When developing the tooth geometry of a spiral bevel gear, the first step is to convert the terminology to pinion instead of gear.

The normal system is more convenient for manufacturing helical gears. In addition, the helical gears must be the same helix angle. The opposite hand helical gears must mesh with each other. Likewise, the profile-shifted screw gears need more complex meshing. This gear pair can be manufactured in a similar way to a spur gear. Further, the calculations for the meshing of helical gears are presented in Table 7-1.

Design of spiral bevel gears

A proposed design of spiral bevel gears utilizes a function-to-form mapping method to determine the tooth surface geometry. This solid model is then tested with a surface deviation method to determine whether it is accurate. Compared to other right-angle gear types, spiral bevel gears are more efficient and compact. CZPT Gear Company gears comply with AGMA standards. A higher quality spiral bevel gear set achieves 99% efficiency.

A geometric meshing pair based on geometric elements is proposed and analyzed for spiral bevel gears. This approach can provide high contact strength and is insensitive to shaft angle misalignment. Geometric elements of spiral bevel gears are modeled and discussed. Contact patterns are investigated, as well as the effect of misalignment on the load capacity. In addition, a prototype of the design is fabricated and rolling tests are conducted to verify its accuracy.

The three basic elements of a spiral bevel gear are the pinion-gear pair, the input and output shafts, and the auxiliary flank. The input and output shafts are in torsion, the pinion-gear pair is in torsional rigidity, and the system elasticity is small. These factors make spiral bevel gears ideal for meshing impact. To improve meshing impact, a mathematical model is developed using the tool parameters and initial machine settings.

In recent years, several advances in manufacturing technology have been made to produce high-performance spiral bevel gears. Researchers such as Ding et al. optimized the machine settings and cutter blade profiles to eliminate tooth edge contact, and the result was an accurate and large spiral bevel gear. In fact, this process is still used today for the manufacturing of spiral bevel gears. If you are interested in this technology, you should read on!

The design of spiral bevel gears is complex and intricate, requiring the skills of expert machinists. Spiral bevel gears are the state of the art for transferring power from one system to another. Although spiral bevel gears were once difficult to manufacture, they are now common and widely used in many applications. In fact, spiral bevel gears are the gold standard for right-angle power transfer.While conventional bevel gear machinery can be used to manufacture spiral bevel gears, it is very complex to produce double bevel gears. The double spiral bevel gearset is not machinable with traditional bevel gear machinery. Consequently, novel manufacturing methods have been developed. An additive manufacturing method was used to create a prototype for a double spiral bevel gearset, and the manufacture of a multi-axis CNC machine center will follow.

Spiral bevel gears are critical components of helicopters and aerospace power plants. Their durability, endurance, and meshing performance are crucial for safety. Many researchers have turned to spiral bevel gears to address these issues. One challenge is to reduce noise, improve the transmission efficiency, and increase their endurance. For this reason, spiral bevel gears can be smaller in diameter than straight bevel gears. If you are interested in spiral bevel gears, check out this article.

Limitations to geometrically obtained tooth forms

The geometrically obtained tooth forms of a spiral gear can be calculated from a nonlinear programming problem. The tooth approach Z is the linear displacement error along the contact normal. It can be calculated using the formula given in Eq. (23) with a few additional parameters. However, the result is not accurate for small loads because the signal-to-noise ratio of the strain signal is small.

Geometrically obtained tooth forms can lead to line and point contact tooth forms. However, they have their limits when the tooth bodies invade the geometrically obtained tooth form. This is called interference of tooth profiles. While this limit can be overcome by several other methods, the geometrically obtained tooth forms are limited by the mesh and strength of the teeth. They can only be used when the meshing of the gear is adequate and the relative motion is sufficient.

During the tooth profile measurement, the relative position between the gear and the LTS will constantly change. The sensor mounting surface should be parallel to the rotational axis. The actual orientation of the sensor may differ from this ideal. This may be due to geometrical tolerances of the gear shaft support and the platform. However, this effect is minimal and is not a serious problem. So, it is possible to obtain the geometrically obtained tooth forms of spiral gear without undergoing expensive experimental procedures.

The measurement process of geometrically obtained tooth forms of a spiral gear is based on an ideal involute profile generated from the optical measurements of one end of the gear. This profile is assumed to be almost perfect based on the general orientation of the LTS and the rotation axis. There are small deviations in the pitch and yaw angles. Lower and upper bounds are determined as – 10 and -10 degrees respectively.

The tooth forms of a spiral gear are derived from replacement spur toothing. However, the tooth shape of a spiral gear is still subject to various limitations. In addition to the tooth shape, the pitch diameter also affects the angular backlash. The values of these two parameters vary for each gear in a mesh. They are related by the transmission ratio. Once this is understood, it is possible to create a gear with a corresponding tooth shape.

As the length and transverse base pitch of a spiral gear are the same, the helix angle of each profile is equal. This is crucial for engagement. An imperfect base pitch results in an uneven load sharing between the gear teeth, which leads to higher than nominal loads in some teeth. This leads to amplitude modulated vibrations and noise. In addition, the boundary point of the root fillet and involute could be reduced or eliminate contact before the tip diameter.

editor by czh 2023-01-07

China manufacturer & factory supplier for Diameter in Panama City Panama 20 inches minimum and 24 Maximium slewing ring bearing gear ring for Hydraulic Man Lifting Aerial Platform With high quality best price & service

ISO 9001:2015 qualified company and distributor of roller chains. Kinds of roller chains consist of ASME/ANSI standard chains, attachment chains, corrosion resistant chains, lube-free chains, plastic chains, free-circulation chains, specialty chains and British common chains. ASME/ANSI regular chains are available in large and small pitch, double pitch and leaf designs. Roller chains are utilised in foodstuff packaging, forklift vehicles, oilfield drilling, motorcycles, conveyors and electrical power transfer programs.Our goods are utilized in a lot of fields.

Overview

Rapid Information

- Applicable Industries:

-

Developing Content Stores, Producing Plant, Farms

- Manufacturer Title:

-

OEM

- Application:

-

syf

- Precision:

-

ABEC3-5-7-nine

- Equipment:

-

No Equipment

- Rolling element:

-

GCr5

- Content:

-

50Mn/42CrMo/Customized

- Operating tempereature:

-

syf

- Load route:

-

Radial bearing

- RACEWAY hardness:

-

fifty five~62HRC

- nner and outer ring modulation hardness:

-

229-268HB

-

Shear bolt torque limiter (SB) EPG Team gives higher top quality PTO shafts with tubes set by spring pin, cross joints with roller bearings with rollers

- Substantial operational efficiency:

-

compact design

Source Ability

- Supply Capability:

- 1500 Established/Sets for every Month

Packaging & Shipping and delivery

- Packaging Particulars

- The oil is lubricated to avoid the drying from currently being sealed with a nylon plastic bag and stored in a picket box.

- Port

- China any Port

-

Direct Time

: -

Amount(Bags) 1 – one hundred >100 Est. Time(times) seven To be negotiated

On the web Customization

Our products is well-known exported to the United States, Germany, Australia, Russia, Spain, Hungary, Zimbabwe, Ukraine, Nigeria, Peru, Brazil, Middle and South The usa, Thailand, Pakistan, Indonesia, much more than 60 countries and regions.

We – EPG – Ever power Transmission Co Ltd. is a single of the most significant transmission firm situated in HangZhou close to Xihu Lake.

We – EPG – Ever power Transmission Co Ltd. is a single of the most significant transmission firm situated in HangZhou close to Xihu Lake.

Why Pick Us

Merchandise Description

1. Integration of factories and trade to makes certain

that each and every doing work process of the item

can be strictly controlled.

2. Competitive good quality and reduced value.

three. Superior technology, specialist packaging,

rapidly shipping and delivery, and designed sea, land and air logistics.

four. Timely right after-product sales support ensures that consumers

have a great encounter.

Single row four point

contact ball slewing bearing

Single row cross

roller slewing bearing

Double Row

Ball slewing bearing

A few row

roller slewing bearing

Roller/Ball Combination

Slewing bearing

|

Kind |

• Single row four level contact ball slewing bearing • One row crossed cylindrical roller slewing bearings • Double row ball slewing bearings •Double row Roller/ball combiThe merchandise we offer in the Standard section are distinguished by substantial flexibility, rapid availability and economic efficiency. alpha Value Line, our modular gearbox series, is a great illustration right here. It meets the requirements of performance classes in which specialized and financial elements have to be concurrently optimized.nation slewing bearing •Three-Row Roller Slew Ring Bearing |

|

Rollng elements |

Metal ball / Cylinder Roller |

|

Rollng elements Content |

GCr5/GCr15SiMn/Customized |

|

Bearing Materials |

50Mn/42CrMo/42CrMo4V /Tailored |

|

Cage Content |

Nylon/ metal /copper |

|

Composition |

taper pin , Mounting holes,Interior ring ,grease fitting,load plug, seals , roller ,spacer balls or separators |

|

Outer diameter |

50-10000mm |

|

Bore dimension |

50-10000mm |

|

Mounting hole |

By means of hole/Tapped hole |

|

Raceway hardness |

fifty five-62HRC |

|

Interior and outer ring modulation hardness |

229-269HB/Custom-made |

|

Gear sort |

No gear ,Inside equipment , External equipment. |

|

Embellish grease |

EP2 lithium lubricating grease |

|

Certification |

Stomach muscles.BV,DNV,ISO9001,GL |

|

Application region |

Ladle turret,Stacker crane,Bucket wheel machine,Photo voltaic heliostat Monitoring Method,port crane, Cabling device,tower crane , offshore system,ferris wheel, Palletizing robotic,Rotary metallurgical furnace,can packing device,Wind blade transporter,defend tunneling equipment,tube press bench,excavator |

|

Manufacturer Name |

HGB |

|

Place of Origin |

HangZhou Henan |

|

Warranty |

twelve months |

|

Payment phrase |

T/T is our first decision |

|

Packing details |

one,Filling with anti-rust oil 2.Corved with Plastic paper three.Corved with kraft paper 4.Corved with Blue tie five.Put in wooden box |

Merchandise Details

Bearing Areas

Metal ball/Roller:carbon-chromium bearing steel GCr15SiMn or GCr15 for rolling Substance

Cage: include integral cage, phase cage and spacer-kind cage. We use 20# steel or copper for integral and section cages, PA 1010 resin or QA110-3-a hundred and five albronze for spacer-type cages.

Seals:makes use of NBR or VITON, number of felted wool.

Solitary row cross roller slewing bearing

It is composed of two or three rings. It has compact construction, gentle fat, large production precision, modest assembly hole and higher necessity for installation precision. Rollers are 1:1 cross-organized. It can bear axial power, overturning instant and massive radial drive at the same time. It is widely utilised in lifting transportation, development machinery and armed forces goods

Three row roller slewing bearing

It have 3 seat rings, the higher and reduced raceways and the radial raceways are separated, so that the load of each row of roller can be determined accurately. Being ready to bear all sorts of hundreds at the same time, it is the largest one of the four structural merchandise with large axle and radial dimensions and agency structure. It is specially ideal for heavy machinery demanding bigger diameter, this sort of as bucket wheel stacker and reclaimer, wheel crane, maritime crane, port crane, ladle turret and big tonnage truck crane. Large equipment and so on.

One row 4 point get in touch with ball slewing bearing.

It is composed of two seat rings. It has compact construction, mild fat, and 4-point make contact with among metal ball and arc raceway. It can bear axial power, radial pressure and overturning moment at the same time. The development equipment of rotary conveyor, welding manipulator, modest and medium-sized crane and excavator can be chosen.

A lot more Merchandise

Interior gear ring

Exterior equipment ring

No equipment ring

About Us

We are situated in the stunning Peony Flower Town, identified as the “Bearing City” of China’s thirteenth historic funds – HangZhou. Is a specialist style, analysis and improvement, creation, income and support in one particular of the slewing bearing built-in entity organization. Relying on the unique advantages of HangZhou aged manufacturer bearing processing base, the business has collected a team of skilled bearing designers and skilled very first-line generation staff, collectively with sophisticated creation and processing equipment and tests tools, to guarantee the high quality of items and related providers from the root..

Extensive production workshop and powerful creation crew as a assistance,guarantee the products can be produced by necessary top quality and quantity. andThereby improve the client benefits.

The above is our manufacturing equipment with advanced engineering , the secure and longevity bearing make from these tools .

We specialize in the production of production slewing ring bearings or turntable Bearings.The Independent R&D and income team in HGB , also do our best for specific needsWe provide high-precision and high-high quality slewing bearings, which are widly utilized in numerous fields,this sort of as hoisting and conveying equipment, development engineering machinery, harbour equipment, wind power era, radar and missile launchers and so on.

Certificate

FAQ

one.Q: Are you trading firm or producer ?

A: We are specialist slewing bearing manufacturer with twenty years’ encounter.

2.Q: How extended is your delivery time?

A: Typically it is 4-5 times if the items are in inventory. or it is forty five times if the products are not in

inventory, Also it is according to quantity.

3.Q: Do you offer samples ? is it cost-free or further ?

A: Yes, we could supply the sample, it is added.

four.Q: What is your conditions of payment ?

A: Payment=1000USD, 30% T/T in progress, stability before shipment.

5.Q: Can you give specific customization according to the operating problems?

A: Confident, we can layout and generate the slewing bearings for various operating problems.

6.Q: How about your guarantee?

A: We supply lifelong following-sales technical support.

Speak to Us

Wechat/Whatsapp: +86 13083988828

Skype: [email protected]

Company Identify: HangZhou EPG – 1 of the bigggest transmission company in China – Ever-Energy Transmission Bearing Technology Co., Ltd

Business office Deal with: Place B8F, Block B, shenhua street 789 – jianqiaogongshe Worldwide, XiHu District, HangZhou Metropolis,China

Cell: +86-13083988828

Factory Address: Bearing zone in XiHu County, HangZhou Metropolis, China